|

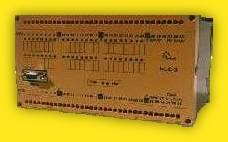

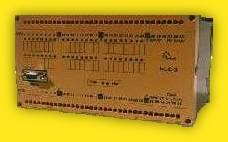

Programmable

controller NLC-3

Description

|

|

Programmable

logic controller (PLC) NLC-3 is a compact

controller dedicated for

realisation of control and regulation functions in various technology,

machines and for data acquisition. NLC-3 includes

processor,

EEPROM and RAM memory, real time clock, RS232 serial interface and maximum

two CAN interfaces. NLC-3 is powered from source 24V DC. The number and the

type of NLC inputs and outputs depends on selection of input and output

boards. Programmable

logic controller (PLC) NLC-3 is a compact

controller dedicated for

realisation of control and regulation functions in various technology,

machines and for data acquisition. NLC-3 includes

processor,

EEPROM and RAM memory, real time clock, RS232 serial interface and maximum

two CAN interfaces. NLC-3 is powered from source 24V DC. The number and the

type of NLC inputs and outputs depends on selection of input and output

boards.

Application software for NLC-3

controllers is developed in graphic

programming system HORSET. Horset was developed by our firm on the

base of French programming system GRAFCET, now probably better known as SFC

- Sequential Function Chart. The main difference between Grafcet a

Horset is the way of writing code. The graphic structure an the instructions

of program states are separated in Grafcet. The graphic structure and the

code instructions are written together in Horset and so the program is very

well readable and understandable even for peoples, that have practically no

experience with programming. Another special

property of Horset is the possibility of integration of many NLC-3

controllers, CIO modules and other products with CAN interface in one

project. NLC-3 knows automatically the state of all inputs and outputs and a

part of variables of other modules and their symbolic names can be used in

NLC program. Thanks to that it is very simple to build large-scale systems.

NLC-3 controllers are inbuilt in robust Dold enclosure

with 66 screw terminals for 35 mm DIN rail. |

|

|

Technical

data

|

Power source |

Power voltage

Power current |

24V±10% DC

max.250 mA |

| Technical

Resources |

Memory

Communication

Real Time Clock

back-up RAM

Watch-dog |

EPROM 64kB

EEPROM 32kB

RAM 128kB

1 channel RS232

2 channels CAN,

max.1Mbit/s

yes

yes, Li battery

100ms |

|

Binary Inputs |

| Number |

max. 24, 24V DC |

|

Analog Inputs |

Number

Range |

max. 16

±5V, ±10V, ±20mA |

|

Transistor Outputs |

| Number |

max. 24 , 24V 0.2A DC |

|

Relay Outputs |

| Number |

max. 24, 230V 5A |

|

Analog Outputs |

Number

Range |

max. 4

0-5V, 0-10V, ±5V, ±10V |

| Mechanical

Description |

Mounting

Dimensions

Mass |

for DIN rail 35mm

200 x 130 x 118 mm

900 g |

|

Working Conditions |

Temperature range

Protection |

0 ~ 50°C

IP 20 |

|

Connection |

Inpits/Outputs

CAN 1

CAN 2

RS232 |

66 screw terminals, wire cross-section

max. 2,5mm2 9 pin CANON

9 pin CANON |

Programming system HORSET

Horset

development was inspired by GRAFCET and SFC (Sequential Function Chart)

part of IEC1131-3 standard.

The program combines graphic

structure of control process with description of instructions executed at the

states and conditions determining transitions of control process from one state

to another.

Instructions executed

at the state are written immediately to the right and down from the state

graphic shape. The transition logic condition is written to the right and down

from the transition graphic shape. Any state can have many transitions to

different next states. The transition conditions are evaluated from the left to

the right till some of them is true. At this moment control process goes to the

state subsequent the active transition, executes instructions written at this

states and evaluates its conditions.

Horset allows to create

parallel processes. Any control process can create one or more next parallel

processes. Two or more control processes can join to one process. The control

process can be also killed by other process. The states of active parallel

processes are executed step by step. At one program control loop active state

instructions and its transition conditions of any active parallel process is

executed. The state instructions are executed only once. If no transition

condition of the state is true, only transition conditions of the state are

evaluated in the next loop. NLC-3 allows minimum one and maximum 16 active

parallel processes at one moment.

Inputs, outputs,

variables and fields symbolic names are defined at tables. Variables can be

defined as boolean, byte, integer and long type. Fields are of integer type. The

names of inputs, outputs and variables of other NLC systems connected by CAN and

included in project can be used like its own.

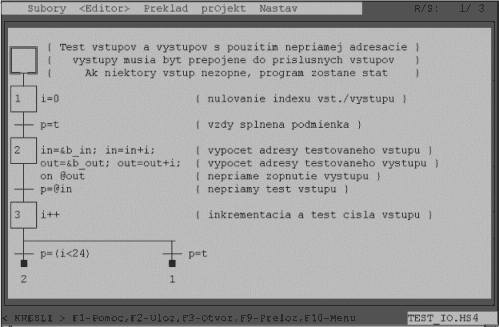

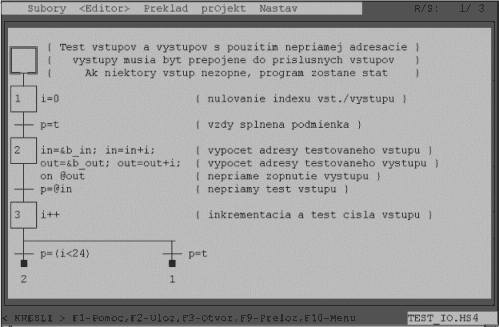

At this picture you can see a simple

program - the test of 24 NLC-3 inputs and outputs by using indirect

addressing. At the first state index variable i is zeroed. The

condition for transition to the next state is always true. At the state 2 at the

first line the address of tested input is calculated. The base address of

tested inputs is assigned to in variable at first and the the

index variable i is added. The address of switched on output is calculated at

the second line of state 2. The base address of tested outputs is assigned to

out variable at first and the the index variable i is added. The

output with calculated address is switched on by instruction on @out

at the third line.

The condition for transition from state 2 to state 3 is

true, when the input with indirect address @in is switched on.

Index variable i is incremented at the state 3. The state 3 has 2 alternative

conditions for transition to the next state. If index variable i is less then

24, program goes to state 2 and tests the next input. If i is equal 24, program

goes to state 1 and starts the new test cycle.

Horset programming system was

developed by programmers with wide experience of control systems implementation

in different types of technology. We developed and implemented at the end users

control systems of robots, monorail transport systems, weighing systems, data

acquisition systems, temperature regulation systems, etc.,etc. Thanks to that

Horset contains a lot of useful instructions that allows write application

software quickly, effectively and the software is well readable and

understandable.

Programmable

logic controller (PLC) NLC-3 is a compact

Programmable

logic controller (PLC) NLC-3 is a compact